Success Study of a Household Goods Manufacturer

Company Profile

- Established household goods manufacturer

- 2,500 employees

- Annual revenue of approx. €450 million

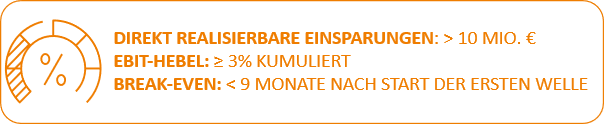

Result: Through a targeted transformation in procurement, the client was able to develop purchasing from a pure cost factor into a strategic value generator: €10 million savings, ≥ 3% cumulative EBIT leverage, < 9 months break-even.

The starting point for the transformation roadmap was a four-week maturity analysis of the six pillars of strategic procurement.

Strategy

Findings

- No documented procurement strategy, category or supplier strategies

- Focus on short-term price optimization instead of value creation

- Global sourcing processes are non-transparent and driven by misaligned incentives

- Lack of systematic market orientation and risk assessment

- No regular exchange with product management, quality management, or sales

Risks

- Increased compliance and supply risks, resource drain through complexity, prevention of sustainable value creation

Recommendations

- Develop a holistic procurement strategy with clear objectives

- Introduce a procurement manual & systematic risk assessment

- Optimize sourcing model including compliance guidelines

- Quarterly workshops with internal stakeholders

Expected Benefits

10–15% savings through strategic bundling, transparent governance, better risk management, and innovation enablement; +1.5% EBIT leverage within 18 months

Processes

Findings

- Strong manual component, mainly Excel-based

- Long alignment cycles, inefficient product development

- Hardly any supplier management, no standardized workflows

- Returns and inventory processes unclear

Risks

- High time and resource requirements, error-proneness, lack of transparency, no risk control, shadow documentation, unclear inventories, and increased return rates

Recommendations

- Standardize & digitize procurement processes

- Implement systematic supplier management (incl. tenders & benchmarking)

- Clear process documentation and responsibilities

- Automate demand planning & returns processes

Expected Benefits

More efficient workflows with lower error rates and time savings (-40% time); Improved supplier performance and transparency; ROI through process cost reduction within 9 months

Organization

Findings

- Unclear roles & responsibilities; procurement operationally overloaded

- Inefficient interfaces with QM, sales, graphics

- High staff turnover, missing middle management layer

- Dependency on individuals

Risks

- Interface conflicts, duplicate work, slow decisions, knowledge loss, dependency on individuals, and lack of international governance

Recommendations

- Establish structured knowledge management

- Introduce a middle management layer

- Stronger integration of procurement into core processes

- Promote international collaboration

Expected Benefits

20% shorter time-to-market; Fewer conflicts and faster decision-making (+20% speed); more stable organization with better synergy utilization (-15% process costs); scalability and resilience.

Employees

Findings

- Knowledge concentrated on few individuals

- No clear target agreements, career paths, or development plans

- Insufficient technical and strategic know-how

- Generational change within the organization

- Innovation management not established

Risks

- Knowledge loss due to turnover, low motivation and retention, overload in complex decisions, lack of innovation impulses

Recommendations

- Define clear roles and objectives

- Introduce target agreements & development paths

- Qualification and training programs for strategic tasks

- Establish idea and innovation management

Expected Benefits

Safeguarding and broadening know-how (+30% motivation, -30% onboarding time); Higher employee retention and innovation capability (+20% value contribution); risk minimization during staff turnover.

Systems & Tools

Findings

- Outdated tools, high manual effort

- SAP only partially used, Excel & email dominate

- No central supplier database

- No basis for automation & AI

Risks

- High time effort and error-proneness, lack of transparency, no foundation for automation/AI, insufficient data for decisions

Recommendations

- Implement modern, integrated procurement systems

- Build a central supplier database

- Digitize & automate routine tasks

- Deploy AI-based tools (forecasting, benchmarking)

Expected Benefits

Time savings and lower error rates (+50% process speed, -30% process costs); improved data quality and capacity for strategic work; payback in <12 months.

Performance Management / KPIs

Findings

- No clear procurement KPIs; success measured only by sales/revenue

- No reporting on supplier performance or portfolio profitability

- Measures not tracked; reporting ad-hoc

Risks

- No control mechanisms or transparency, no success monitoring or continuous improvement

Recommendations

- Introduce clear procurement KPIs (e.g. savings, delivery reliability, TCO)

- Establish regular reporting & review processes

- Focus on value contribution instead of volume

- Build a transparent performance culture with KPI dashboard

Expected Benefits

Measurable results and continuous improvement; Greater transparency and stronger positioning of procurement as value driver; real-time management for data-driven decisions and EBIT improvement.

Implementation of the Transformation Roadmap

The transformation program was executed in three waves:

Wave 1 – Building the Foundation & Quick Wins

- Develop spend overview for transparency

- Create overarching procurement strategy incl. pilot projects (e.g. category management)

- Introduce first KPIs and dashboard structures

- Implement quick savings via tenders and negotiations

→ Goal: Activate first EBIT levers, break-even < 9 months

Wave 2 – Strategic Alignment & Organization

- Align procurement consistently with corporate goals

- Develop category strategies and define category leads

- Build a scalable and resilient organization with clear roles

- Realize largest savings potentials in categories

→ Goal: Position procurement as strategic value driver

Wave 3 – Enablement & Performance Phase

- Sustainable anchoring of competencies (skill-gap analysis, development paths, academy)

- Strengthen innovation (e.g. supplier co-creation, innovation challenge days)

- Establish performance culture with live dashboards & regular KPI reviews

→ Goal: Continuous improvement, higher transparency, and EBIT increase

Author:

Contact:

Kloepfel Group

Damir Berberovic

Tel.: +49 211 941 984 33 | Email: rendite@kloepfel-consulting.com