No matter if customer, supplier, subcontractor or freight forwarder. The SCOR model illuminates even the darkest corners of the supply chain. With the right application, high efficiency and cost potentials can be realized.

The Supply Chain Operations Reference Model (SCOR model) is a supply chain management concept which was developed by the Supply Chain Council in 1996. The aim of the SCOR model is to provide a basis for supply chain optimization, allowing a precise representation of the six primary management processes: planning, procurement, production, delivery, return delivery and supporting processes. These processes include any interaction with own customers and suppliers as well as their customers and suppliers. The model deliberately excludes the areas of marketing, sales and research. The supply chain council regularly changes the model on the basis of current market conditions and requirements.

Basics of the model

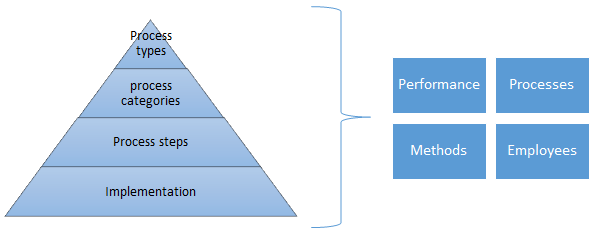

The SCOR model is a hierarchical process model based on three cross-industry dimensions, which, when implemented in practice, must be expanded by a fourth, company-specific dimension.

The different process types of the supply chain are recorded in the first step. These include the primary management processes already mentioned. Planning includes activities such as obtaining information about the required resources or capacity planning. In this way, a plan for operating the supply chain is to be drawn up. The procurement processes the order of goods and services, which are important for the creation of value chain. Procurement is also responsible for the delivery and storage of these goods. Procured materials are then processed by production and converted into products of any kind. Logistics then organizes all processes related to the supply of customers. In the course of the return delivery, the returning material flow is controlled from the customer to the supplier. After all, the supporting processes that deal with the general management of the supply chain remain. These include, for example, data and performance management or risk management.

The second level of the process model depends on the predominant process category and thus also determines the operational strategy. This is where the decision is made about whether make-to-stock, make-to-order, engineer-to-order or other processes will be used within the supply chain.

The second level of the process model depends on the predominant process category and thus also determines the operational strategy. This is where the decision is made about whether make-to-stock, make-to-order, engineer-to-order or other processes will be used within the supply chain.

At a glance: Our Infographic

The four modules of the SCOR model

In addition to the hierarchical structure, the SCOR model is based on four major thematic blocks:

- Performance

The performance of the supply chain is measured by the five attributes reliability, speed, agility, costs and asset management efficiency. Each attribute is subject to different KPIs, starting with Level 1 KPIs such as perfect order fulfillment, which, for example, determines reliability. This key figure in turn is based on other level 2 and level 3 key figures, such as adherence to delivery dates or delivery flexibility. This makes it possible to determine exactly which key figures need to be optimized in order to fulfill the final attribute and thus improve performance.

- Processes

The area “processes” refers to the already presented process model. There are a total of four process levels, which consist of sub-processes and make the supply chain transparent.

- Methods

The SCOR model contains a collection of precious methods that apply to all sectors. These methods are characterized by their uniqueness, which is reflected in the model by factors such as the degree of automation or technological innovation. SCOR distinguishes between four levels of quality: Future methods, proven methods, standard methods and obsolete methods.

- Employees

In order to implement the processes and methods defined by SCOR, different skills are required, depending on the process, which the employees must have. SCOR classifies these skills in order to establish a five-level hierarchy of competencies, starting with beginners, who have neither experience nor training and need precise instructions. This is followed by the newcomers, who do their work but cannot reflect and classify it. Level three is the level of the competent, who understand connections and priorities their work. Then come the experienced ones, who have all aspects of the work in mind and can adapt to the situation, and last but not least the experts who are distinguished by intuitive understanding and innovative thinking.

These four aspects form the basic framework and are described in detail in a document of almost 1,000 pages. They have to be considered and evaluated both in their function as an individual component of the model and on the basis of their relationship to each other.

Conclusion

The SCOR model is particularly suitable for companies with complex and diverse supply chains, as it not only enables them to manage their entire process chain, but also to improve it. By involving all parties in the supply chain, problems can be quickly identified at every process level and eliminated with the right measures. In order to apply the model effectively, however, a clean implementation is required. Each area of the model has to be applied individually and company dependent in order to achieve the best results.

Further articles and information about Kloepfel Consulting can be found here:

Contact

Kloepfel Group

Christopher Willson

rendite@kloepfel-consulting.com

Phone: +4921187545323