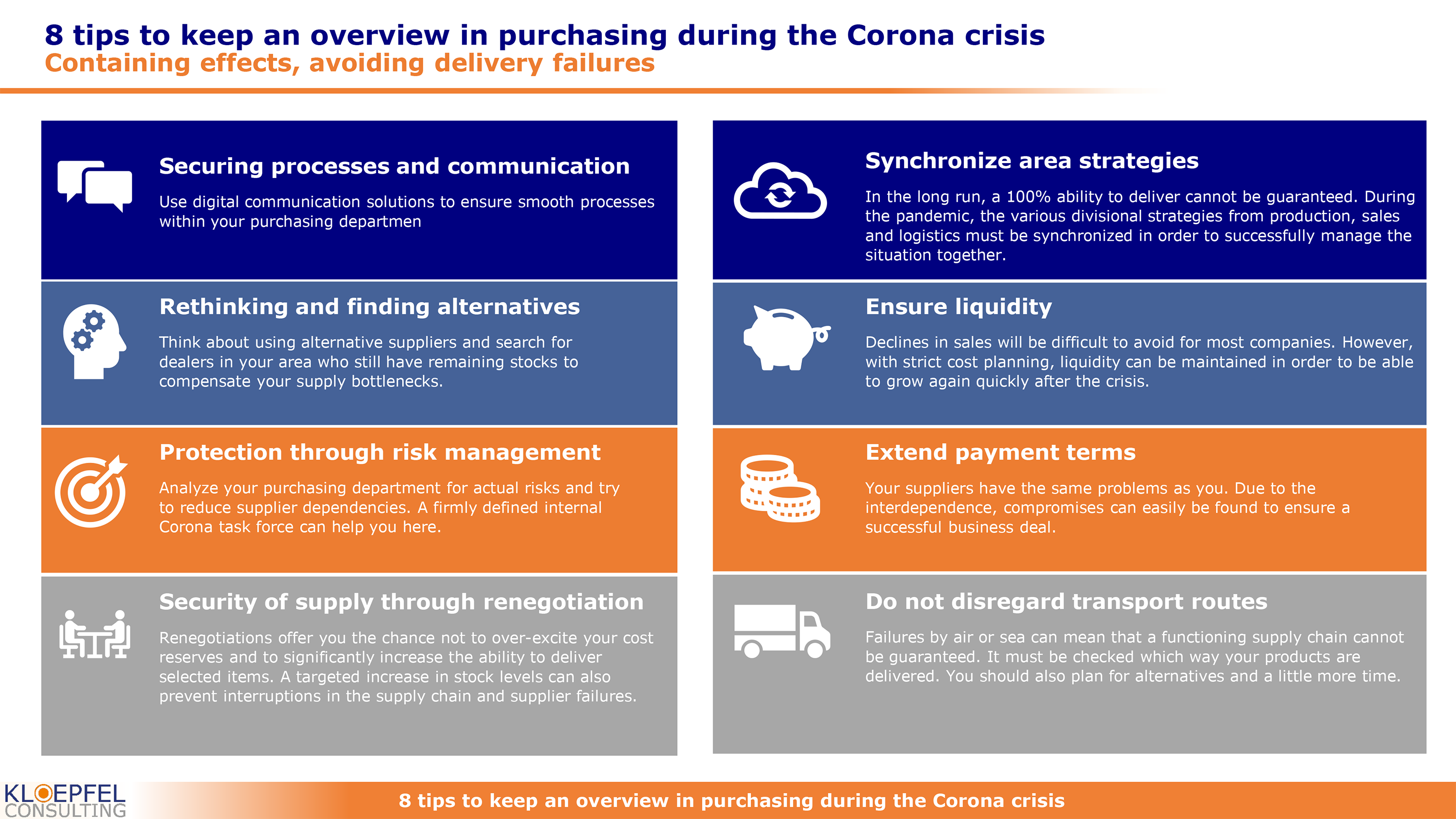

Contain effects, avoid delivery failures

1. Digital solutions for smooth processes in purchasing

Home office for all employees is already mandatory in most companies. But this makes internal and external communication with colleagues and suppliers more difficult. Especially in purchasing, negotiations and detailed agreements are part of the agenda. In order to keep on doing so, digital communication solutions such as Microsoft Teams are a good choice. The versatile functions allow the purchasing department to maintain standard processes.

2. Rethinking and finding alternatives

In a crisis situation, it is of the highest priority for Purchasing to ensure the flow of critical materials and services. The supply in the majority of markets is already very scarce at present, which is why the use of alternative suppliers or the purchase of remaining stocks from local dealers should be considered.

3. Keeping a cool head and risk management Limiting delivery failures

The one who keeps a cool head always emerges successfully from crises. Don’t make hasty decisions, but analyse your purchasing department to identify actual risks. To find effective solutions and preventive measures, it must be clear which product groups are threatened and to what extent. If there is a real threat of delivery failures, it is important to determine the consequences for your purchasing department. In the course of this, it is advisable to set up an internal task force which will intensively deal with the effects of the coronavirus on purchasing.

4. Security of supply through renegotiation and increase in stock

Renegotiations offer you the chance not to overexcite your cost reserves. A success factor at this point is the consolidation of your purchasing volume. By restructuring the order quantities and the timing of the order, the ability to deliver articles purchased from different stock suppliers can be significantly increased. You can also prevent interruptions in your supply chain by specifically increasing the stock levels of important items.

5. Synchronize division strategies

At the present time, we must assume that the current situation will not ease for the time being. For the purchasing department, this means that a 100% ability to deliver cannot be guaranteed in the long term. At this point, an exchange with the production, sales and logistics departments is indispensable. During the pandemic, the various divisional strategies must be synchronized in order to successfully manage the situation together.

6. Maintaining liquidity

During the Corona crisis, cost management also comes to the fore. In purchasing in particular, it must be determined which goods and services are absolutely necessary for business operations. Based on this, non-critical expenses should be minimized to ensure liquidity. It is important that all purchases are also handled by the purchasing department and maverick buying is avoided. Because without an overview of all costs no precise cost analysis can be carried out.

7. Do not disregard transport routes

Although your supplier is capable of production, have you also checked whether the transport routes are working properly? Failures by air or sea can mean that a functioning supply chain cannot be guaranteed. It is therefore of particular importance to investigate in advance which route your products will be delivered and to have alternatives for a possible disruption in the supply chain. Delays due to customs controls should also be taken into account.

8. Make compromises with suppliers

Your suppliers currently have the same problems as you. Delivery failures and bottlenecks affect the entire industry. All the more reason for all parties to do business and maintain existing business relationships. This in turn means that suppliers are willing to compromise, for example to grant longer payment terms. This can also secure your liquidity and prove valuable in the long term.

Source: www.kloepfel-consulting.com